3 Strategies from Leaders that Thrived

Just-In-Time Manufacturing is more complicated now and requires more effort for a small manufacturer in challenging times

Just-In-Time (JIT) manufacturing has become more complex and demanding for small manufacturers during challenging times:

- Supply Chain Volatility

Global disruptions—like pandemics, geopolitical tensions, and shipping delays—have made it harder to receive materials exactly when needed. Small manufacturers lack the leverage to prioritize shipments, making JIT riskier and more resource-intensive. - Inventory Risk Tradeoffs

JIT minimizes inventory, but in uncertain times, this increases the risk of production halts. Small firms must now invest more time in contingency planning or hold buffer stock, which contradicts JIT’s core principle. - Vendor Reliability Issues

JIT depends on dependable suppliers. However, smaller manufacturers often rely on a limited vendor base, which may struggle with their own disruptions, forcing more effort into sourcing, vetting, and managing alternatives. - Increased Administrative Load

Maintaining JIT under stress requires tighter coordination, real-time tracking, and frequent schedule adjustments. Without large-scale automation, small teams must manually manage these complexities, diverting focus from core operations. - Cost Pressures and Cash Flow

JIT was designed to reduce costs, but volatile pricing and urgent procurement needs can lead to higher expenses. Small manufacturers must now balance JIT efficiency with financial flexibility, often requiring more strategic planning and oversight.

The importance of marginal gains for a small manufacturer

For small manufacturers, especially in uncertain markets, the principle of marginal gains—making small, incremental improvements across operations—can yield significant competitive advantages. Rather than relying on sweeping changes, focusing on 1% improvements in multiple areas can lead to substantial overall performance boosts.

- Optimize Repetitive Processes

Identify routine tasks—like order entry, material handling, or packaging—and streamline them. Even shaving off a few seconds per task can accumulate into hours saved weekly. Use checklists, visual aids, or simple automation tools to reduce errors and increase consistency. - Enhance Supplier Communication

Improving how and when you communicate with suppliers can reduce lead times and prevent costly delays. Set up regular check-ins, share forecasts, and use digital tools to track shipments. A more responsive supply chain supports leaner inventory and better customer service. - Invest in Workforce Skills

Upskilling employees in areas like quality control, equipment maintenance, or digital tools can lead to fewer defects, less downtime, and more innovation. Encourage cross-training and reward small improvements suggested by staff—they often know where the biggest gains can be made.

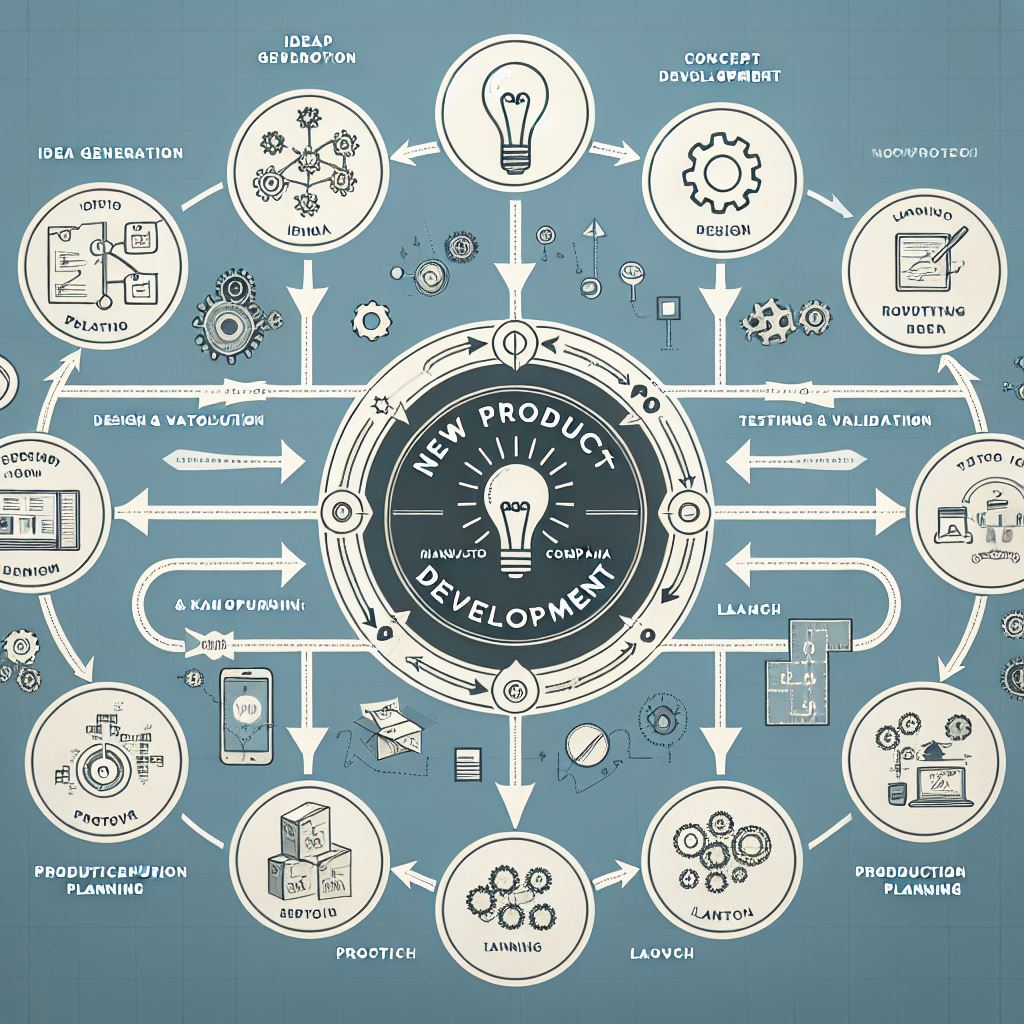

We learned we needed to expand new product development during the lockdown, and are benefiting now.

During the lockdown, we recognized the need to broaden our new product development efforts. That strategic shift is now paying off, positioning us for stronger growth and resilience. Here’s how:

- Diversified Revenue Streams

By developing new products, we reduced our dependence on a narrow product line. This diversification has helped us better navigate market fluctuations and customer demand shifts. - Faster Innovation Cycles

The urgency of the lockdown forced us to streamline our development process. We adopted leaner methods, enabling quicker prototyping and faster time-to-market—an advantage we continue to leverage today. - Stronger Customer Relationships

Engaging customers early in the development process helped us tailor solutions to their evolving needs. This not only improved product-market fit but also deepened trust and loyalty.